This is done by production managers so they can easily calculate their cost of goods sold and cost of goods manufactured. A predetermined manufacturing overhead rate can also be helpful when making a manufacturing overhead budget. As the name implies, these are financial overhead costs that are unavoidable or can be canceled. Among these costs, you’ll find things such as property taxes that the government might be charging on your manufacturing facility. But they can also include audit and legal fees as well as any insurance policies you have.

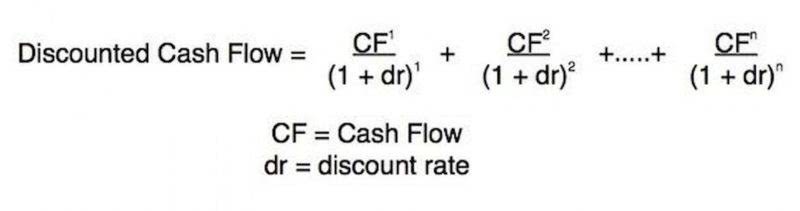

How do you calculate predetermined overhead rate in accounting?

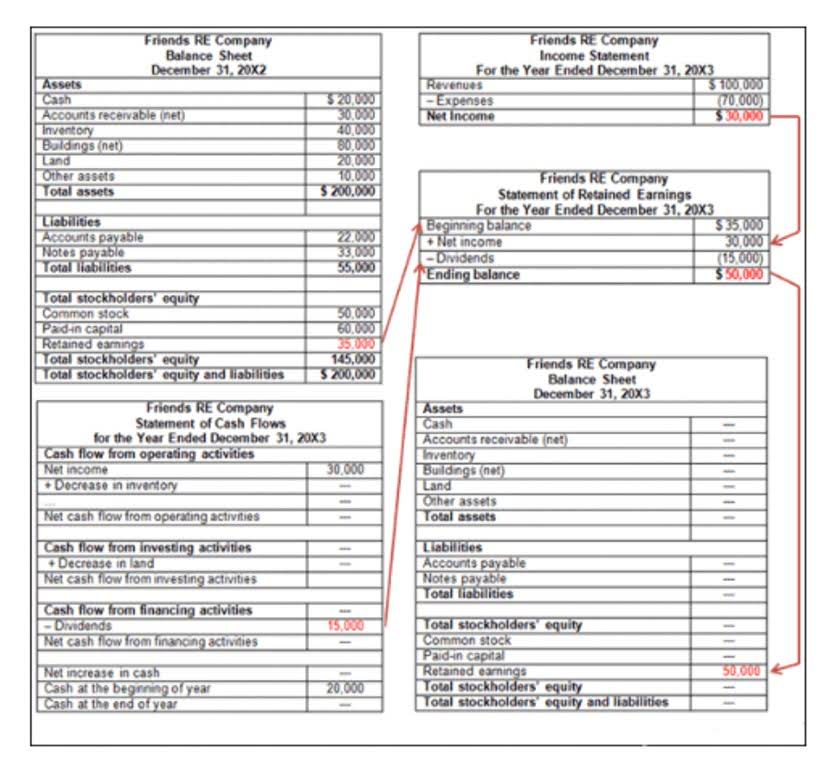

For example, labor-intensive products might use direct labor hours, while highly automated lines might use machine hours. The goal is to choose the base that most accurately reflects how overhead costs behave for each product type. Manufacturing overhead is added to the units produced within a reporting period and is the sum of all indirect costs when creating a financial statement.

Step-by-Step Guide to Calculate Total Manufacturing Cost

- The amount of overhead applied to a specific product or job is determined by multiplying the predetermined overhead rate by the actual allocation base used by that product or job.

- Accurately calculating total manufacturing costs is essential for profitability.

- If there is more than one canteen (e.g. worker’s canteen, supervisor’s canteen, and officer’s canteen), each canteen should be treated as a separate cost centre.

- With features for task and resource management, workload and timesheets, our flexible software can meet the needs of myriad industries.

- It is often difficult to assess precisely the amount of overhead costs that should be attributed to each production process.

Knowing how to find total manufacturing costs allows businesses to compete how to find manufacturing overhead rate better in the market and optimize their production processes. The first step in calculating manufacturing overhead costs involves comprehensive identification of all relevant overhead components within your production environment. Begin by conducting a thorough audit of your manufacturing facilities, documenting every expense that supports production but doesn’t directly become part of the finished product. This includes obvious costs like factory utilities, indirect labor (maintenance staff, production supervisors, quality control personnel), and facility-related expenses (rent, property taxes, insurance). Creating exhaustive expense categories ensures no significant overhead costs slip through the cracks during calculation. To calculate total manufacturing costs, you need to add up three key components – direct materials, direct labor, and overhead costs.

Fine-Tune Calculations with Variable Variables

Companies should repeat the overhead calculation process periodically to ensure that costs remain consistent with the company’s overall objectives. A lower overhead cost will mean more money will be available for activities that directly increase profits, such as expanding production capacity or investing in research and development. Sales represent the sum of all revenue generated by the sale of goods and services in a gross vs net certain period. After these figures are determined, they can plug them into the formula to determine the overhead manufacturing rate. Financial costs include any costs incurred while preparing financial statements or other reports required by regulatory bodies or creditors.

- Then we added the fixed manufacturing overhead for each month to obtain the total manufacturing overhead values.

- To understand how you use your labor resources efficiently, you need to know how your labor cost compares to your total overhead cost.

- They usually include the cost of the property where the manufacturing is taking place and its depreciation, purchasing new machines, repair costs of new machines and other similar costs.

- Try us out for 14 days for free, and rest assured your overhead costs will be kept in check.

- Under this method, moving average is calculated with reference to figures for the 12 months immediately preceding the month for which the rate has to be determined.

Contra Account: Definition + Examples (FREE Checklist Included)

These costs are necessary for production but do not physically become part of the product itself. This category is often referred to as factory overhead or production overhead. Identifying manufacturing overhead https://ssds.ng/equity-multiplier-formula-definition-explained/ is crucial for accurate product costing, setting competitive prices, and preparing reliable financial reports. Proper accounting for these costs ensures the true expense of manufacturing is reflected, aiding profitability analysis. If Department B has overhead costs of $30,000 but direct costs of $70,000, then its overhead rate is 43%. Despite having lower total overhead, Department B is less efficient since its overhead rate is higher.